3D printing and how it advances the incredible work done at a university

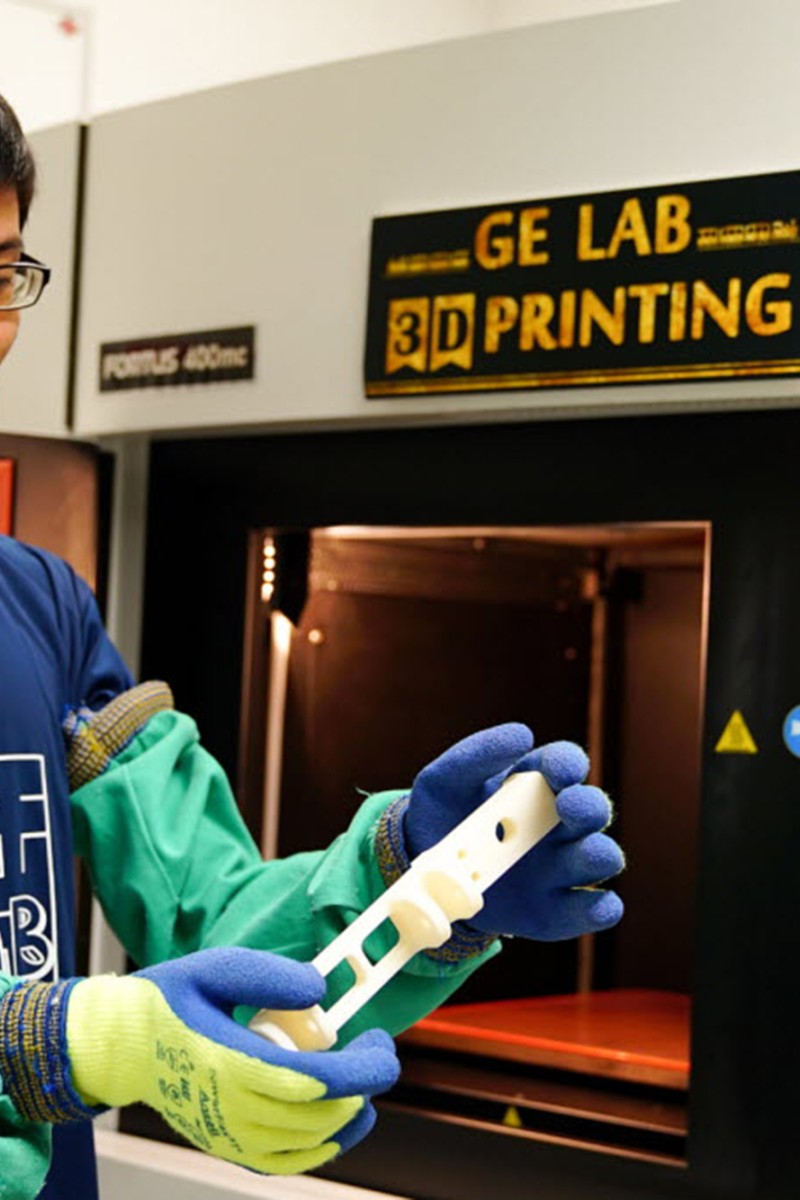

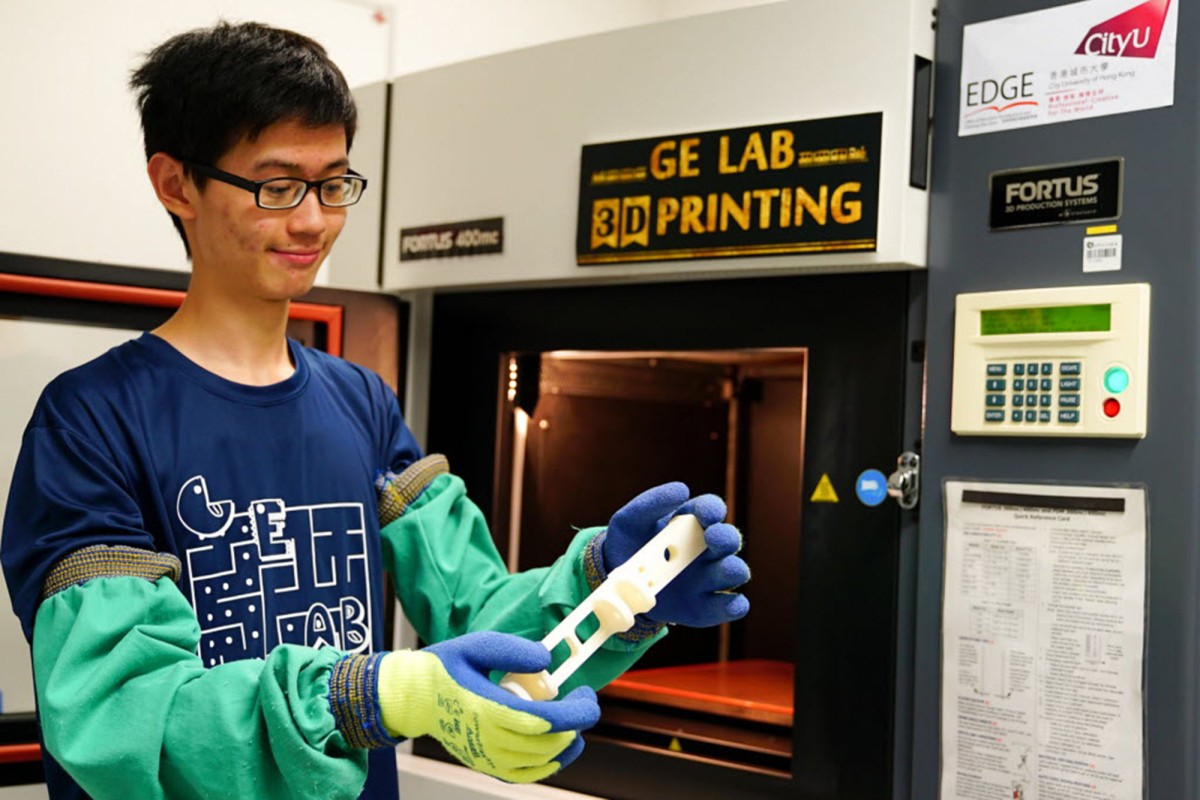

Keith Choi creates 3D-printed prototypes for research projects ranging from bioengineering to architecture.

Keith Choi creates 3D-printed prototypes for research projects ranging from bioengineering to architecture.This is my third article about 3D printing technology at City University of Hong Kong (CityU). Previously, I introduced the principles and the limitations of 3D printing technology. Now I am going to talk about the practical use of 3D printers inside the Gateway Education Laboratory at CityU from the perspective of a student helper in the only 3D printing laboratory on campus.

Our laboratory‘s rapid use of 3D printers has already boosted the research process of many projects, in areas as diverse as bioengineering, electronic engineering and Chinese architectural study.

Most projects involve research and development (R&D) cycles that can take months to finish, and involve lots of modifications during or after each cycle. Fortunately, 3D printing greatly reduces the time and cost of these modifications, and thus speeds up the cycle itself.

For example, on a recent biotech research project, I collaborated with two post-doctoral students to develop unique experiment apparatus for their project.

Many projects have special requirements, and need to test various prototypes to find the best results. This project was no different.

One morning, we had a meeting to discuss the designs of experiment apparatus. We had to consider the capability of our 3D printers and also the limitations of the materials.

That afternoon, I finished the modifications by using the appropriate 3D design software. And after an overnight 3D printing process we had an entirely new prototype for further testing.

In this way, we shortened the time required from months to weeks. That is why so many students and professors are interested in applying this technology in their projects.

But the situation outside the university is entirely different. The use of 3D printers in Hong Kong is generally just beginning. Many companies and organisations may be interested in it, but they are still learning how to use this technology.

In addition, compared to the relatively slow uptake in Hong Kong, 3D printing is developing at an unbelievable rate across the globe in different fields, from building and construction to aerospace engineering and the food industry.

If Hong Kong wants to maintain its competitive edge in the global market, it will have to learn how to use 3D printing; otherwise we will get left behind.