HKU mechanical engineering students head to France as Airbus Fly Your Ideas 2017 competition finalists

Published:

Listen to this article

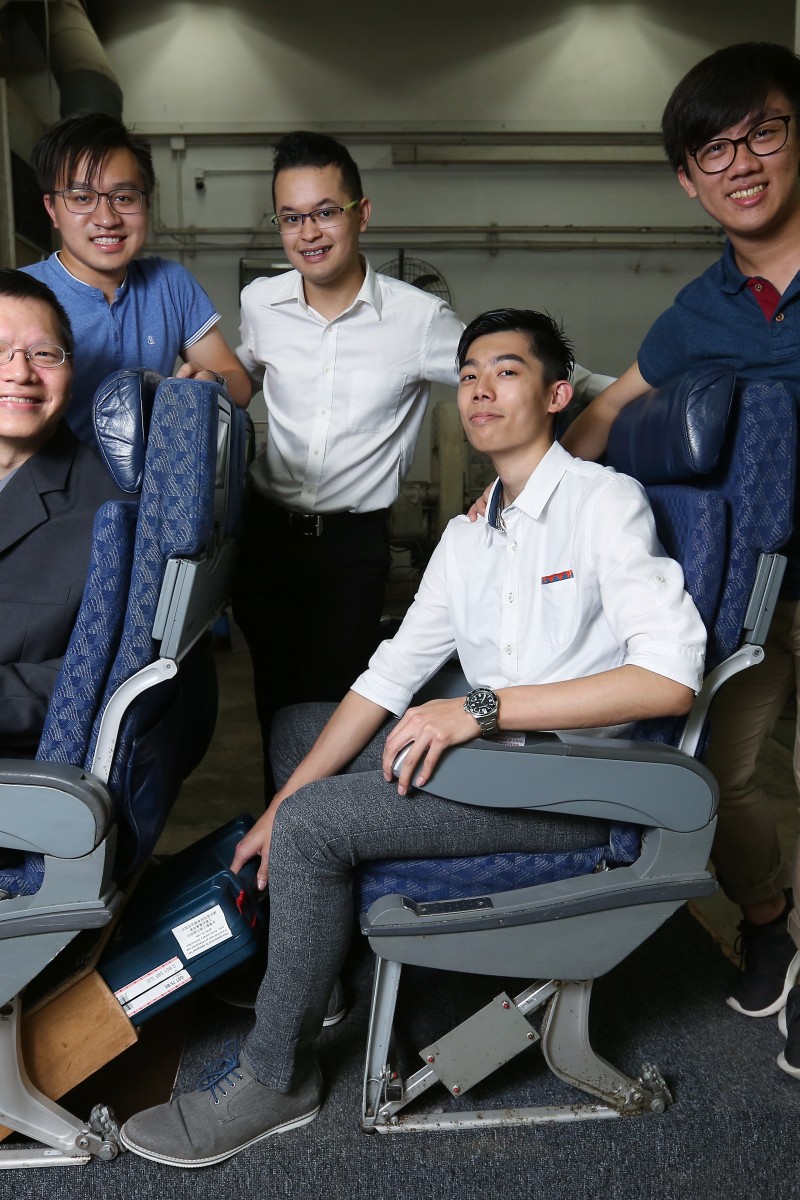

Four mechanical engineering students from HKU are heading to Toulouse, in France, to compete in the final round of a student design challenge for Airbus

Young Wang |

Published:

Sign up for the YP Teachers Newsletter

Get updates for teachers sent directly to your inbox

By registering, you agree to our T&C and Privacy Policy

Sign up for YP Weekly

Get updates sent directly to your inbox

By registering, you agree to our T&C and Privacy Policy